Water Jet Cutting, Machining and Fabrication

Made to Your Drawings

We have had thousands of satisfied customers since 2002 in the following areas:

No part or quantity is too small. Components are made from 6-4 titanium, S7, 4130, 4140, fortal aluminum, etc., with a quick turnaround.

All jobs will be time and material, and no quotes will be provided.

Why are there no quotes?

High Precision Water Jet Cutting

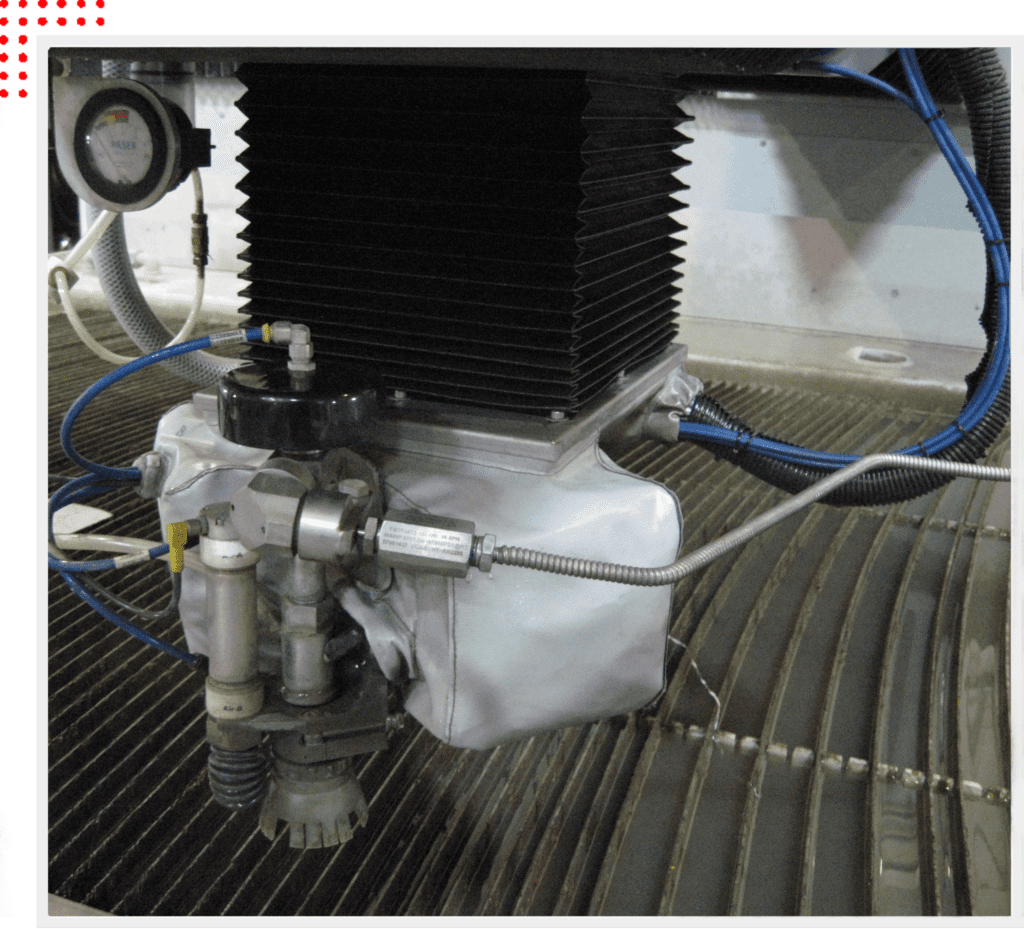

Quality water jet cutting since 2008. There are many water jets in the Midwest, but ours is one of the few that has both ultra-high pressure (87,000 psi) and a dynamic head. This means your parts will have better, high-precision edges and be cut faster at less cost.

For water jetting, e-mail us at: [email protected]

Need Parts Made?

Why Should Your Parts Be Cut by a Water Jet Over a Laser?

Laser cutting is a very productive process and certainly has its place, usually on thinner material. However, water jets do have several advantages over lasers:

Over milling?

If you are through-cutting the perimeter and holes rather than blind holes or pockets, the abrasive water jet is typically much faster, easier to program, and cheaper than milling. This is due to cutting a part with one pass and not having to reduce all the metal to chip form. In addition, there is minimal setup and fixturing time.

Over plasma or oxy-fuel?

Plasma is a hot process. It adds a great deal of heat to the product, leaving a heat-affected zone. The surface finish of the abrasive water jet part is generally better. It leaves almost no dross on the backside of the part, reducing secondary operations. Abrasive water jet parts can also be much more closely nested.

Design Tips for Water Jet Cutting

Sending Part Drawings [email protected]

Best Method: E-mail a 2D DXF file and PDF with overall dimensions. Also, include the quantity and material in the e-mail.

NOTE: If your part will require additional machining or forming other than just water jet cutting, include a PDF file of the dimensioned part drawing.

PDF file tips:

Acceptable: E-mail, Fax, or send Drawings/Sketches. An actual part could be shipped to us.

NOTE: These methods may incur additional engineering charges to generate the DXF geometry.

Machined Ordered Parts

Step 1

E-mail us the following at: [email protected]

Step 2

We will e-mail you back and let you know

Step 3

E-mail us

Step 4

We will e-mail back confirming we are starting the project.

Step 5

When the project is finished

Step 6

Payment

Note: When paying by check or MO, the total cost will be 2.9% less, but may delay shipping.

Step 7

Shipping